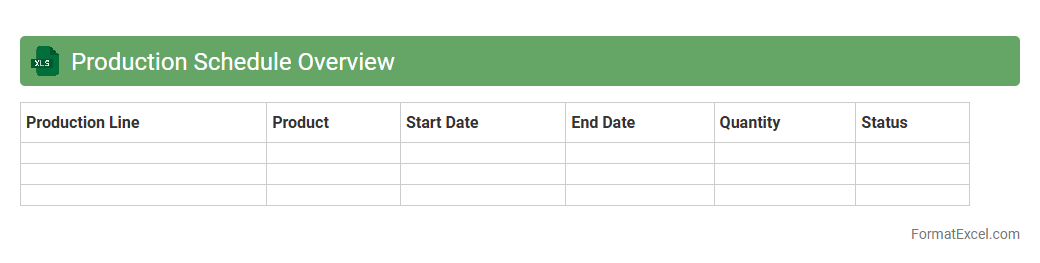

Production Schedule Overview

A

Production Schedule Overview Excel document is a detailed timeline that outlines the sequence and timing of production tasks, resources, and deadlines. It helps manage workflows efficiently by tracking progress, allocating resources, and identifying potential bottlenecks in manufacturing or project execution. This tool enhances productivity, ensures timely delivery, and supports data-driven decision-making in production management.

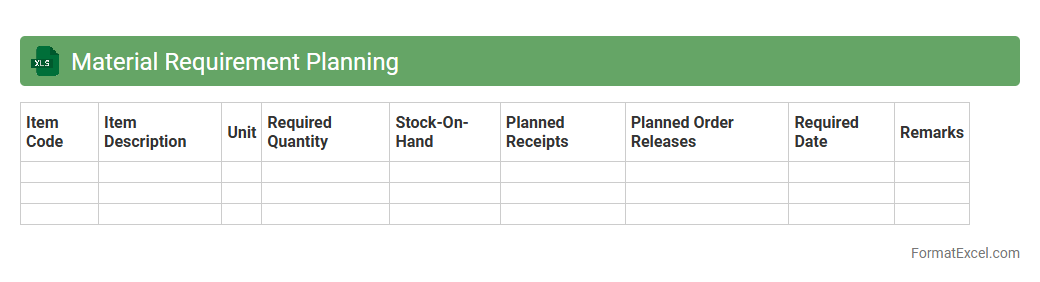

Material Requirement Planning

A

Material Requirement Planning (MRP) Excel document is a spreadsheet tool designed to help businesses efficiently manage inventory levels, production scheduling, and procurement processes. It calculates the quantities of raw materials needed based on demand forecasts, lead times, and existing stock, ensuring timely availability without overstocking. This document is useful for optimizing resources, reducing carrying costs, and streamlining manufacturing workflows.

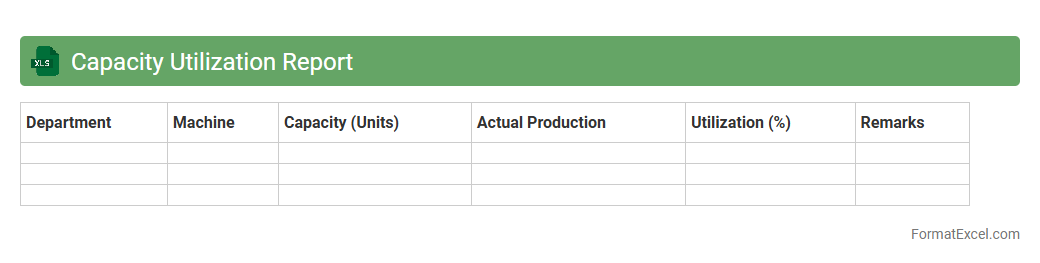

Capacity Utilization Report

A

Capacity Utilization Report Excel document tracks the percentage of available production capacity that is being used within a specific timeframe, providing critical insights into operational efficiency. This report helps businesses identify underutilized resources, optimize production schedules, and forecast potential bottlenecks, leading to improved resource allocation and cost savings. By analyzing the data, managers can make informed decisions to enhance productivity and plan for future capacity expansion.

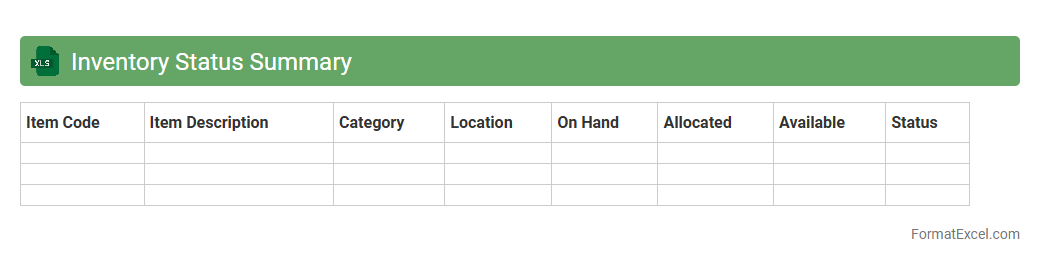

Inventory Status Summary

The

Inventory Status Summary Excel document provides a comprehensive overview of stock levels, item conditions, and movement trends within a business or warehouse. It helps track available inventory, identify shortages or surpluses, and optimize reorder schedules to maintain efficient supply chain operations. By consolidating crucial inventory data into one accessible format, it supports informed decision-making and improves resource management.

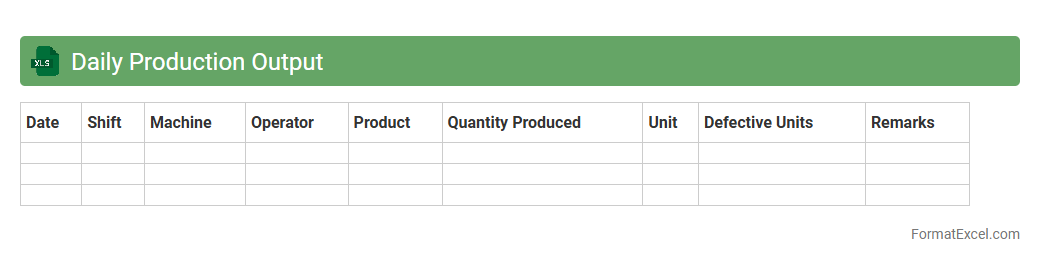

Daily Production Output

The

Daily Production Output Excel document tracks the quantity and quality of goods produced each day, enabling efficient monitoring of operational performance. It consolidates data such as production volume, machine uptime, and defect rates, which helps identify trends and areas for improvement. This document is essential for optimizing resource allocation, enhancing productivity, and ensuring timely decision-making in manufacturing processes.

Work Order Tracking

A

Work Order Tracking Excel document is a structured spreadsheet used to monitor and manage the lifecycle of work orders, including job details, status, assigned personnel, and deadlines. It enhances operational efficiency by providing real-time visibility into task progress, resource allocation, and completion timelines. This tool helps reduce errors, streamline communication, and ensure timely delivery of projects within organizations.

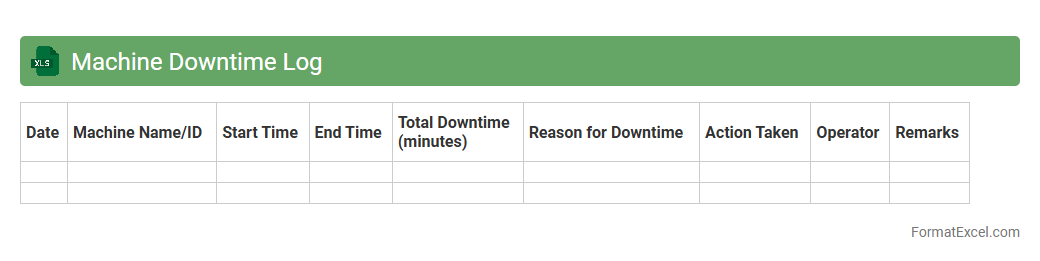

Machine Downtime Log

A

Machine Downtime Log Excel document systematically records periods when machinery is non-operational, detailing the start and end times, reasons for downtime, and associated impacts. This log enables precise analysis of production inefficiencies, facilitates root cause identification, and supports data-driven maintenance scheduling. Utilizing such a document improves operational efficiency by minimizing unplanned downtime and optimizing maintenance activities.

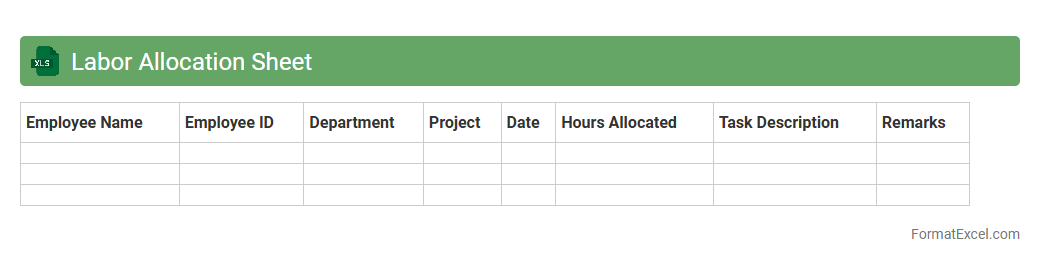

Labor Allocation Sheet

A

Labor Allocation Sheet Excel document is a tool designed to track and manage the distribution of workforce hours across various projects or tasks within an organization. It helps supervisors and project managers monitor employee productivity, ensure efficient utilization of labor resources, and maintain accurate payroll records. Using this sheet improves project planning, budget control, and overall operational efficiency by providing clear visibility into labor costs and allocation patterns.

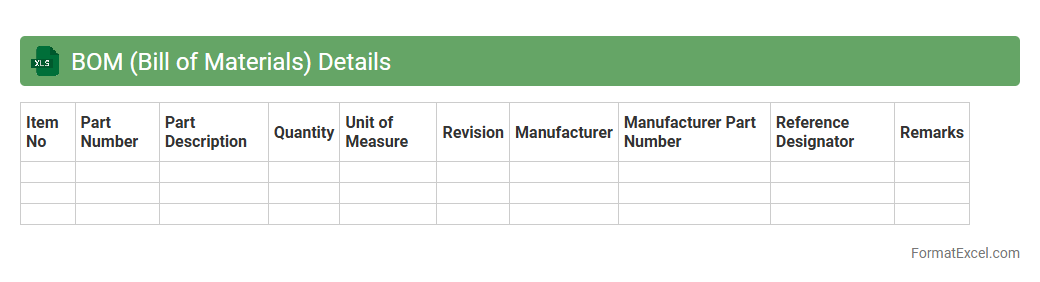

BOM (Bill of Materials) Details

A

Bill of Materials (BOM) Details Excel document is a comprehensive list of raw materials, components, and assemblies required to manufacture a product, organized systematically for easy reference. This document facilitates accurate inventory management, cost estimation, and production planning by providing detailed information on part numbers, quantities, descriptions, and supplier data. Using a BOM Details sheet enhances efficiency in procurement processes, reduces errors in assembly, and supports seamless communication across engineering, manufacturing, and purchasing teams.

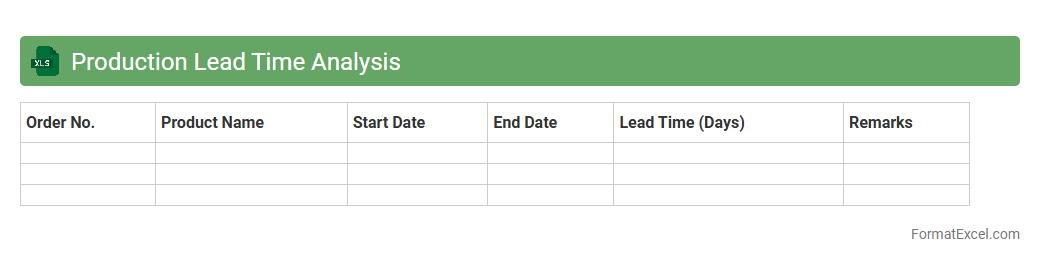

Production Lead Time Analysis

Production Lead Time Analysis Excel document is a tool designed to calculate and visualize the total time required for manufacturing processes, from order initiation to product completion. It helps identify bottlenecks and inefficiencies by breaking down each stage's duration, allowing for data-driven decisions to optimize workflow. Utilizing this

Production Lead Time Analysis enhances operational efficiency, reduces delays, and improves overall production planning accuracy.

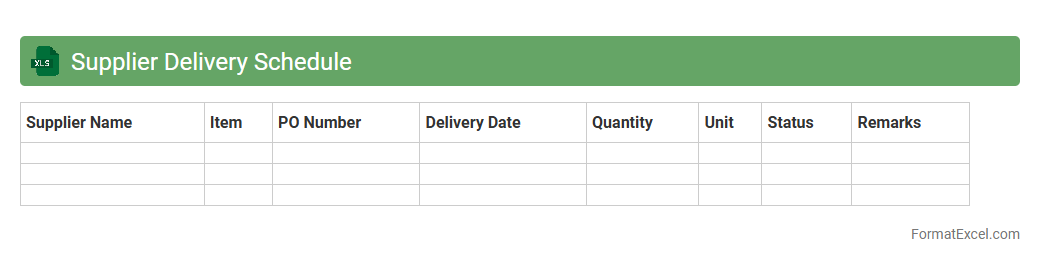

Supplier Delivery Schedule

A

Supplier Delivery Schedule Excel document is a structured spreadsheet used to track and manage the timing and quantities of goods supplied by vendors. It helps organizations monitor expected delivery dates, optimize inventory levels, and coordinate production planning efficiently. Using this document reduces delays, improves supplier communication, and enhances overall supply chain management.

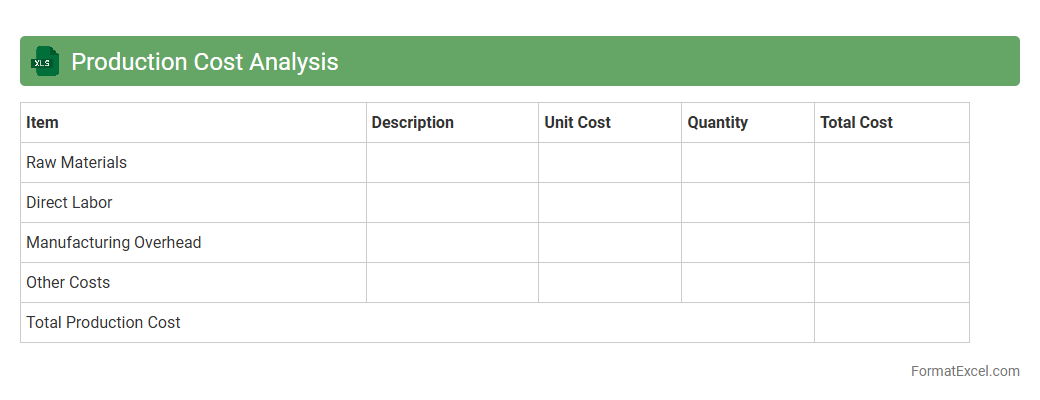

Production Cost Analysis

The

Production Cost Analysis Excel document systematically breaks down all expenses involved in manufacturing a product, including raw materials, labor, and overhead costs. It enables businesses to track, manage, and optimize costs effectively, helping to increase profitability by identifying areas where savings can be made. Using this tool improves decision-making and budgeting accuracy, ensuring resources are allocated efficiently.

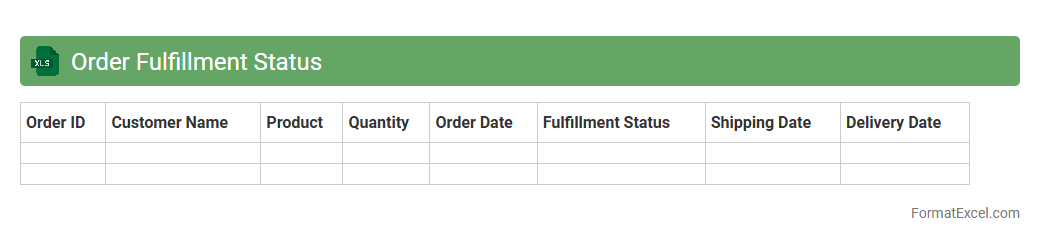

Order Fulfillment Status

An

Order Fulfillment Status Excel document is a detailed spreadsheet used to track the progress of customer orders from placement to delivery. It provides real-time updates on inventory levels, shipping dates, and order completion, enabling businesses to manage supply chain efficiency and improve customer satisfaction. This document is essential for identifying bottlenecks, forecasting demand, and ensuring timely delivery, ultimately optimizing operational workflow.

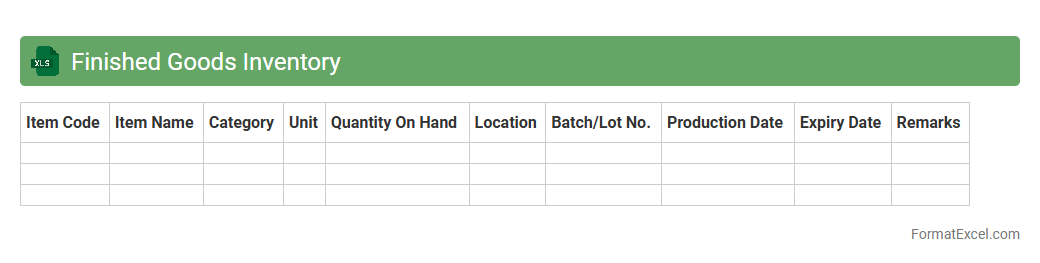

Finished Goods Inventory

A Finished Goods Inventory Excel document is a tool used to track and manage the quantity, value, and status of completed products ready for sale. It helps businesses maintain accurate records of stock levels, streamline inventory control, and optimize order fulfillment processes. Utilizing this document enhances

inventory accuracy and supports efficient decision-making in supply chain management.

WIP (Work in Progress) Tracking

A

WIP (Work in Progress) Tracking Excel document is a tool designed to monitor ongoing projects, inventory, or tasks by recording their current status, estimated completion times, and resource allocation. It enhances project management efficiency by providing real-time visibility into unfinished work, enabling better forecasting, prioritization, and resource optimization. This document helps teams identify bottlenecks early, reduce delays, and maintain smoother workflow continuity.

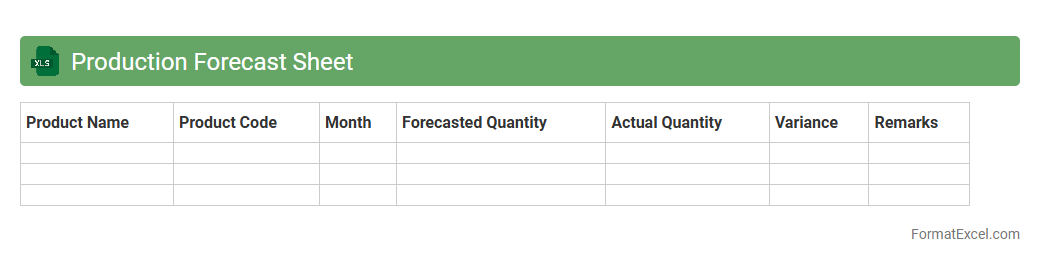

Production Forecast Sheet

A

Production Forecast Sheet in Excel is a detailed document used to estimate future manufacturing output based on historical data, market trends, and resource availability. It assists businesses in planning inventory, scheduling labor, and managing supply chain operations effectively. Utilizing this forecast sheet helps minimize production delays and optimize resource allocation, ensuring smoother operational workflows.

Raw Material Purchase Log

A

Raw Material Purchase Log Excel document is a detailed record-keeping tool that tracks the procurement of raw materials, including quantities, suppliers, prices, and purchase dates. It enables businesses to manage inventory efficiently, monitor supplier performance, and control purchase costs with accuracy. By organizing purchase data systematically, this log supports informed decision-making and ensures smooth production planning.

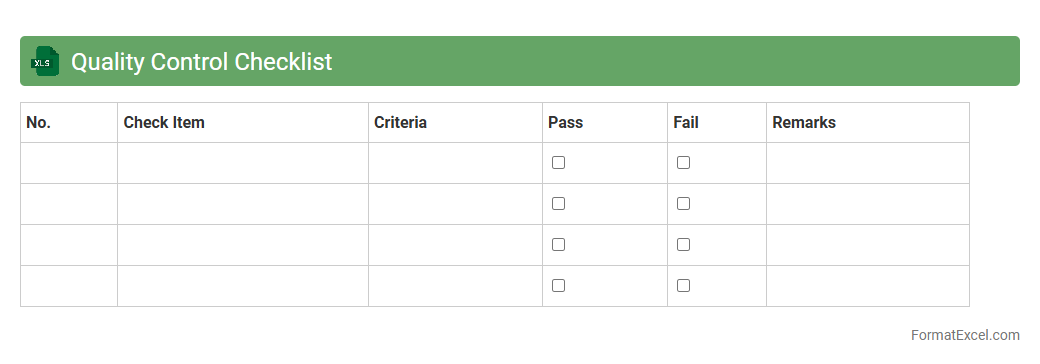

Quality Control Checklist

A

Quality Control Checklist Excel document is a structured tool designed to systematically track and verify product or process quality standards through customizable checklists. It enhances accuracy and consistency by allowing users to record inspection results, monitor deviations, and identify corrective actions digitally. This document streamlines quality management, improves accountability, and supports compliance with industry standards, making it essential for maintaining high-quality outputs.

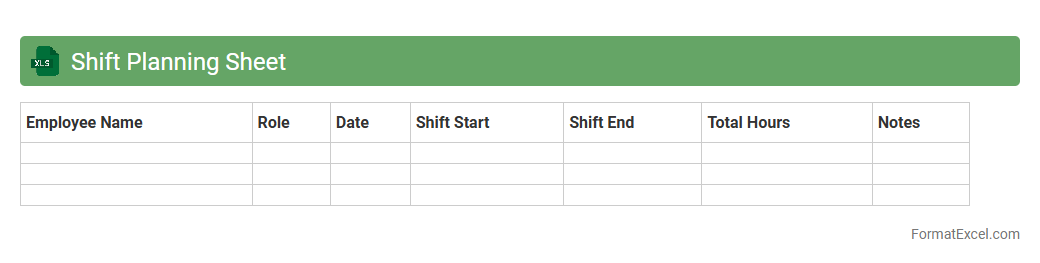

Shift Planning Sheet

A

Shift Planning Sheet Excel document organizes employee work schedules by date, time, and role, enabling efficient workforce management. It helps supervisors allocate shifts, track attendance, and prevent scheduling conflicts, thereby improving overall productivity. Businesses benefit from reduced labor costs and enhanced operational planning through streamlined shift coordination.

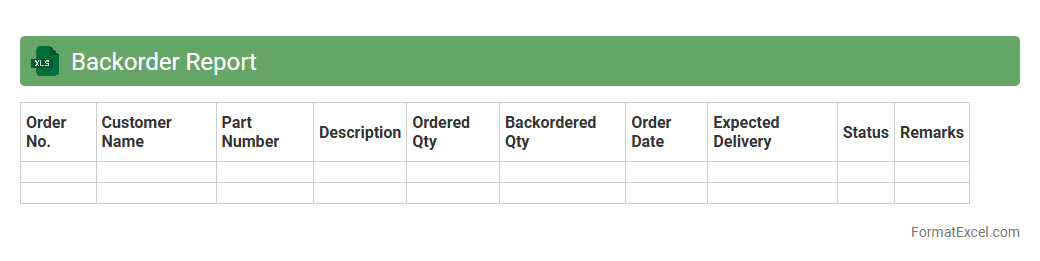

Backorder Report

The

Backorder Report Excel document tracks outstanding customer orders that cannot be fulfilled due to insufficient inventory. It provides detailed insights into product shortages, order quantities, and expected fulfillment dates, enabling efficient supply chain management. This report helps businesses prioritize restocking efforts, minimize customer dissatisfaction, and improve overall inventory planning.

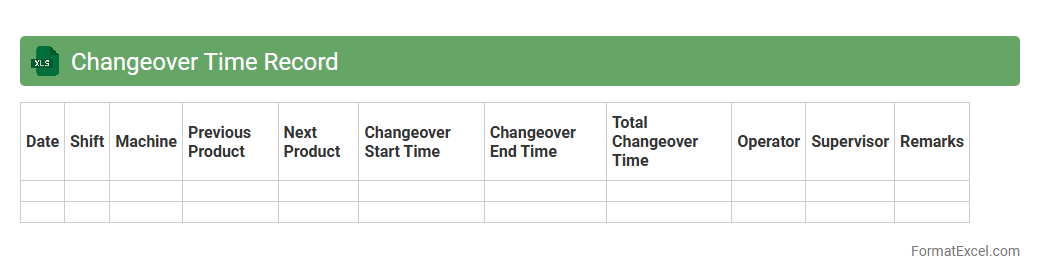

Changeover Time Record

The

Changeover Time Record Excel document is a structured tool designed to track and analyze the time taken for equipment or processes to switch from one task or product to another. It helps identify inefficiencies and bottlenecks in production workflows, enabling targeted improvements to reduce downtime and increase operational efficiency. By maintaining accurate changeover time data, businesses can optimize scheduling, improve resource allocation, and enhance overall productivity.

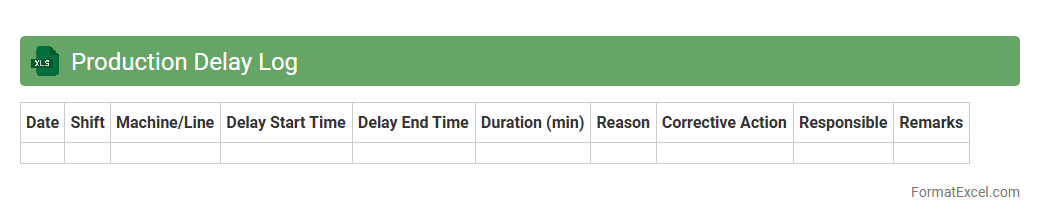

Production Delay Log

The

Production Delay Log Excel document is a tool designed to systematically record and track instances of production delays, including their causes, durations, and impacts on project timelines. It enables teams to analyze patterns, identify bottlenecks, and implement corrective actions to enhance overall efficiency and productivity. Utilizing this log helps organizations minimize downtime, optimize resource allocation, and improve delivery schedules.

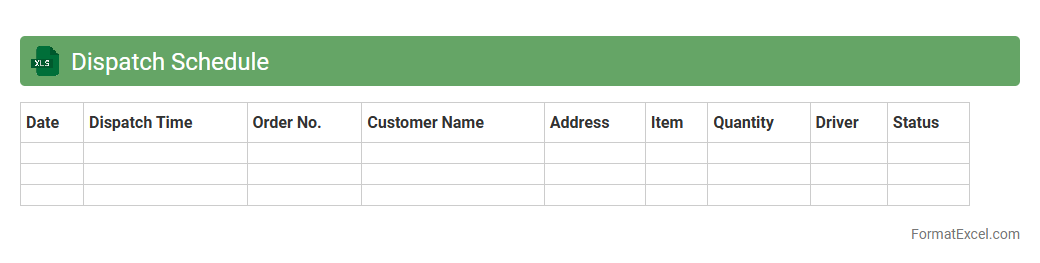

Dispatch Schedule

A

Dispatch Schedule Excel document is a structured spreadsheet used to organize and manage the timing and allocation of deliveries or shipments efficiently. It helps businesses track vehicle routes, delivery times, driver assignments, and load details, ensuring timely dispatch and reducing operational delays. Utilizing this tool enhances logistics coordination, improves resource utilization, and supports timely communication with customers.

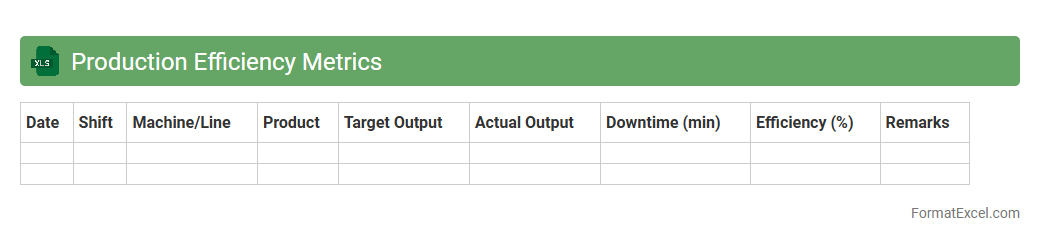

Production Efficiency Metrics

The

Production Efficiency Metrics Excel document is a structured tool designed to track, analyze, and optimize manufacturing processes by capturing key performance indicators such as cycle time, throughput, and defect rates. This document enables businesses to identify bottlenecks, monitor productivity trends, and implement data-driven improvements that enhance operational effectiveness. By providing clear visualizations and automated calculations, it supports informed decision-making and continuous process optimization.

Expedited Order Tracker

The

Expedited Order Tracker Excel document is a powerful tool designed to monitor and manage urgent orders efficiently by consolidating order details, statuses, and deadlines in one place. It helps streamline communication between teams, reduce delays, and ensure timely delivery by providing real-time updates and prioritization. This document enhances operational productivity and customer satisfaction by enabling quick decision-making and clear visibility of high-priority order fulfillment.

Introduction to Production Planner Formats

The Production Planner format is essential for organizing and scheduling manufacturing activities efficiently. It helps track production timelines, resources, and workflows. Using standardized formats ensures clarity and consistency across production teams.

Benefits of Using Excel for Production Planning

Excel offers a flexible and user-friendly platform for production planning, allowing easy customization and data analysis. It supports real-time updates, enabling quick adjustments to schedules. Additionally, Excel's powerful functions facilitate effective resource management and forecasting.

Key Features of an Effective Production Planner

An effective production planner includes clear timelines, resource allocation, and progress tracking. It integrates task dependencies and allows for real-time status updates. Visual aids like Gantt charts enhance understanding and monitoring of production stages.

Essential Columns in a Production Planner Excel Sheet

Critical columns in a production planner include Task Name, Start Date, End Date, Assigned Resources, and Status. Incorporating a Priority or Urgency column helps in managing workflow efficiently. These columns ensure comprehensive tracking and timely completion.

Step-by-Step Guide to Creating a Production Planner in Excel

Start by defining your production tasks and timelines in Excel. Assign resources and add columns for start/end dates and status updates. Use conditional formatting and formulas to track progress and highlight bottlenecks in your planner.

Sample Production Planner Excel Template

A sample template includes pre-defined columns like Task Description, Dependencies, Start/End Dates, and Status. It often features dropdown menus for easy data input and conditional formatting for visual progress tracking. This template simplifies initial setup for production planning.

Customizing Your Production Planner Format

Customize your planner to fit specific production needs by adding columns for cost, quality checks, or machine usage. Tailor formulas and conditional formatting to reflect your workflow priorities. A customized planner enhances accuracy and operational efficiency.

Tips for Optimizing Production Schedules in Excel

Regularly update your planner to reflect real-time progress and potential delays. Use Excel's filtering and sorting features to prioritize urgent tasks. Integrating formulas to calculate lead times and resource availability strengthens your production schedule.

Common Mistakes in Production Planner Excel Sheets

Avoid overly complex sheets that hinder usability and frequent manual data entry errors. Missing critical columns like status or deadlines reduces planning effectiveness. Ensuring proper data validation and regular updates prevents these common mistakes.

Downloadable Production Planner Excel Templates

Many websites offer free or paid downloadable Excel templates for production planning. These templates provide a structured start with built-in features for task tracking and resource management. Utilizing downloadable templates saves time and improves productivity.