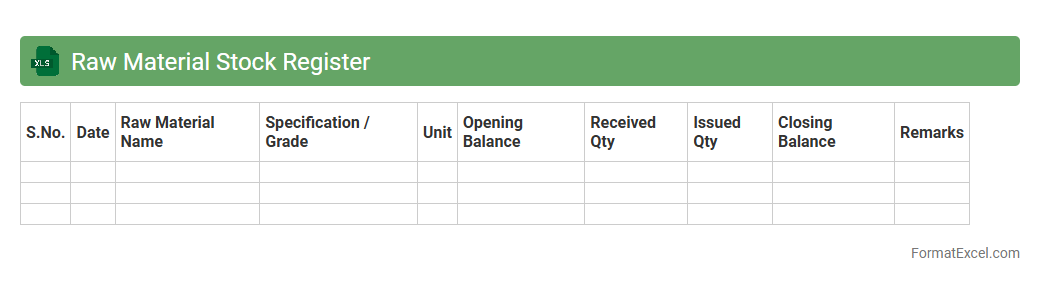

Raw Material Stock Register

The

Raw Material Stock Register Excel document is a detailed spreadsheet that tracks inventory levels, purchase dates, supplier information, and usage rates of raw materials in manufacturing or production processes. It helps businesses efficiently monitor stock availability, prevent stockouts, and optimize procurement planning by providing real-time data on material consumption and replenishment needs. Utilizing this register enhances inventory control, reduces waste, and supports accurate financial reporting for material costs.

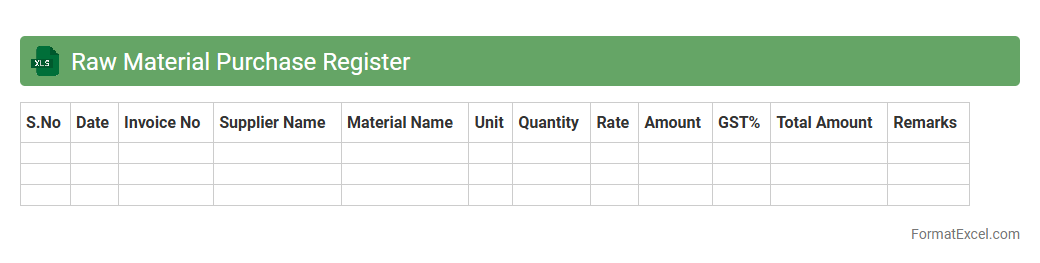

Raw Material Purchase Register

A

Raw Material Purchase Register Excel document is a systematic record-keeping tool that tracks the procurement details of raw materials, including purchase dates, quantities, suppliers, and costs. This register helps businesses maintain accurate inventory levels, monitor supplier performance, and manage budgeting effectively. Using it ensures transparency in purchasing processes and aids in making informed decisions to optimize supply chain operations.

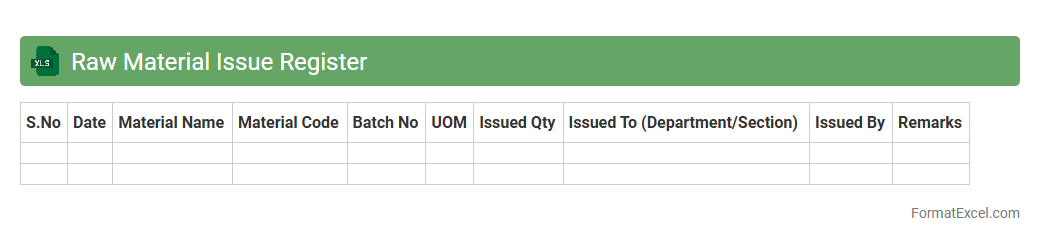

Raw Material Issue Register

The

Raw Material Issue Register Excel document is a detailed record that tracks the issuance of raw materials from inventory to the production floor. It helps maintain accurate inventory control, reduces wastage, and ensures timely availability of materials for manufacturing processes. This register is essential for cost management, production planning, and auditing purposes in any manufacturing setup.

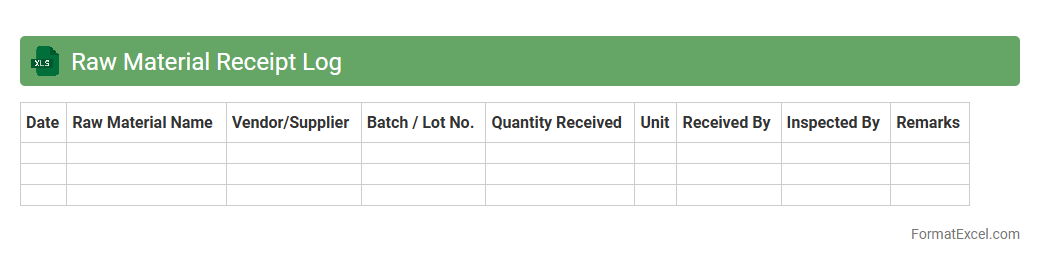

Raw Material Receipt Log

The

Raw Material Receipt Log Excel document is a detailed record-keeping tool used to track incoming raw materials in manufacturing or production processes. It helps ensure accurate inventory management, quality control, and timely procurement by documenting supplier information, quantity received, inspection status, and delivery dates. This log enables businesses to monitor material flow, reduce discrepancies, and streamline supply chain operations effectively.

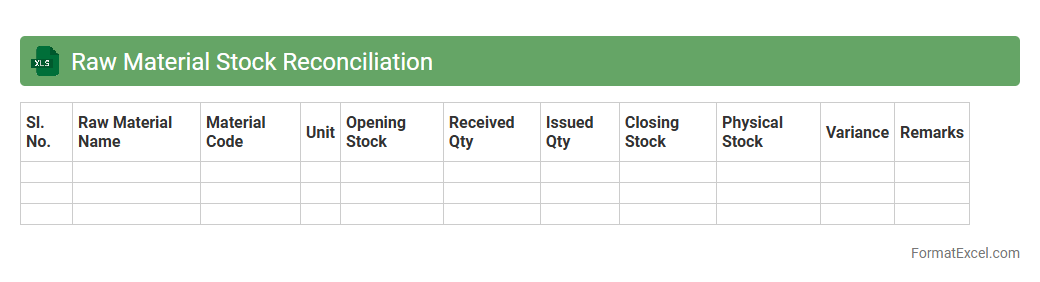

Raw Material Stock Reconciliation

The

Raw Material Stock Reconciliation Excel document is a financial and inventory management tool used to compare and verify the recorded stock levels of raw materials against the actual physical inventory. This helps identify discrepancies, control wastage, and maintain accurate stock records, ensuring efficient procurement and production planning. By providing clear insights into stock variances, the document supports better decision-making and reduces the risk of material shortages or overstocking.

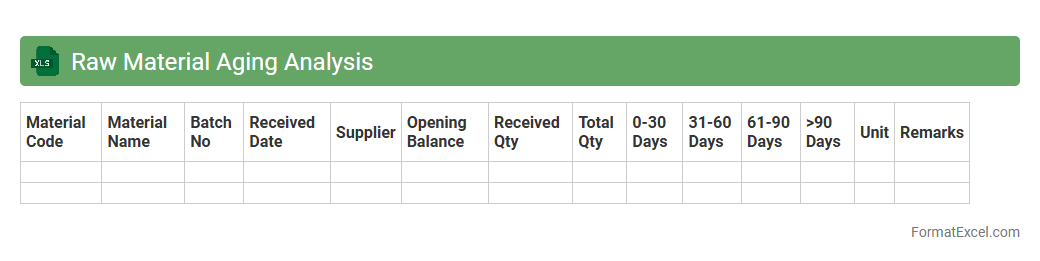

Raw Material Aging Analysis

The

Raw Material Aging Analysis Excel document tracks the age and shelf life of raw materials used in production, enabling better inventory management and reducing waste due to material expiration. It helps identify which batches are nearing their expiry, allowing timely usage or replenishment decisions to maintain product quality. This analysis enhances cost efficiency by minimizing loss and ensuring compliance with safety standards.

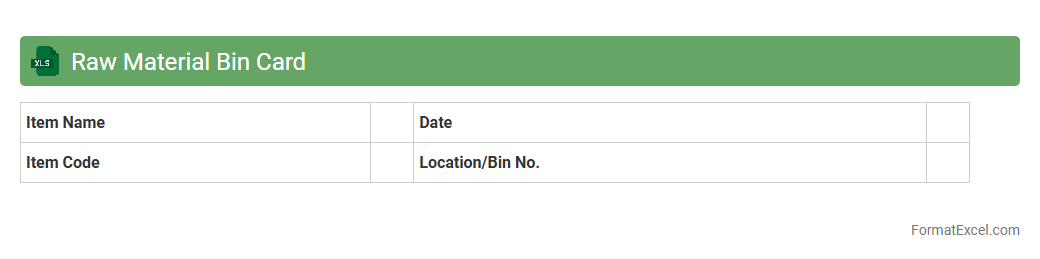

Raw Material Bin Card

A

Raw Material Bin Card Excel document is a digital inventory management tool designed to track raw material quantities, usage, and stock levels in real time. It allows businesses to maintain accurate records of incoming and outgoing materials, preventing stockouts and overstock situations while facilitating efficient procurement planning. By centralizing data in an organized spreadsheet format, it enhances transparency, accountability, and operational efficiency in raw material handling.

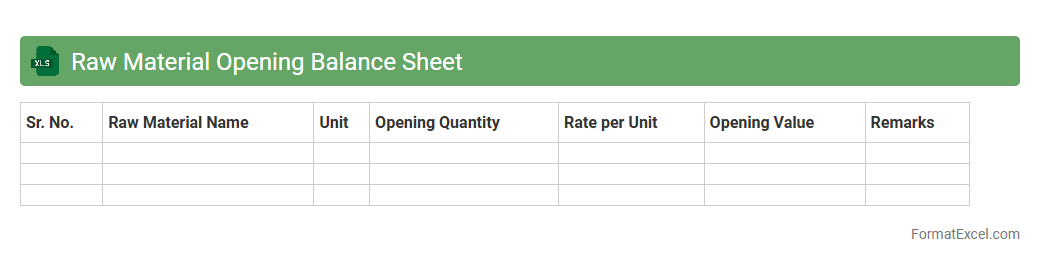

Raw Material Opening Balance Sheet

The

Raw Material Opening Balance Sheet Excel document records the initial quantities and values of raw materials available at the beginning of an accounting period. It provides a clear snapshot of inventory levels, helping businesses track material usage, plan procurement, and ensure accurate cost accounting. This document is essential for maintaining efficient supply chain management and supporting precise financial reporting.

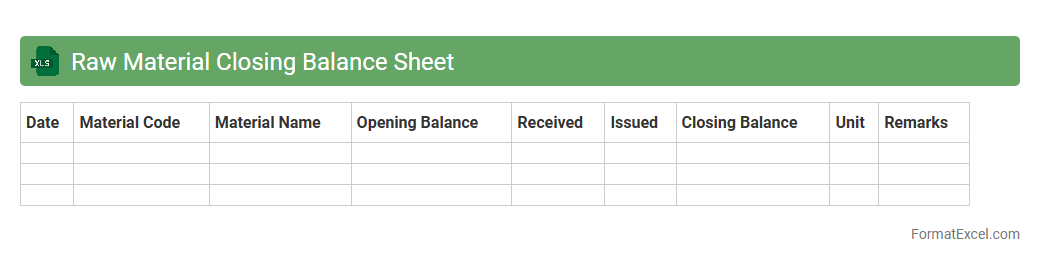

Raw Material Closing Balance Sheet

The

Raw Material Closing Balance Sheet Excel document tracks and summarizes the remaining raw materials at the end of an accounting period, providing a clear snapshot of inventory levels. It is useful for inventory management, cost control, and financial reporting by helping businesses ensure accurate valuation of stock, prevent overstocking or shortages, and support production planning. This document also aids in reconciling accounts and preparing accurate financial statements for better decision-making.

Raw Material Batch Tracking

A

Raw Material Batch Tracking Excel document is a digital tool designed to monitor and record the movement and usage of raw materials in production processes. It provides detailed information such as batch numbers, supplier data, expiration dates, and quantities used, enabling precise inventory management and quality control. By utilizing this document, businesses can ensure traceability, improve compliance with industry regulations, and reduce waste through enhanced tracking of raw material consumption.

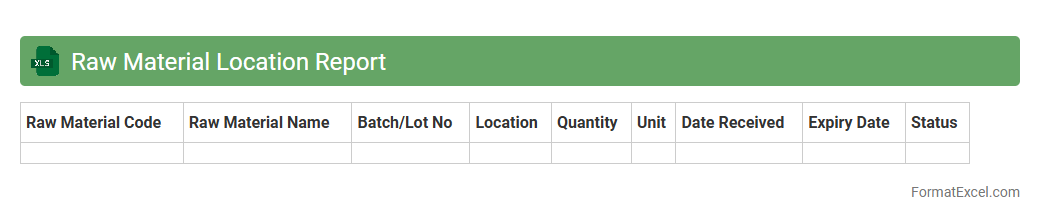

Raw Material Location Report

A

Raw Material Location Report Excel document tracks the precise storage locations of raw materials within a warehouse or production facility, enabling quick identification and retrieval. It enhances inventory management by minimizing search times, reducing stock discrepancies, and streamlining production workflows. This report supports accurate stocktaking, improves resource allocation, and ensures timely availability of materials for manufacturing processes.

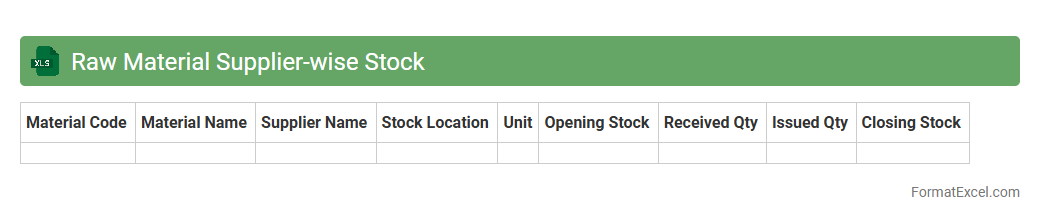

Raw Material Supplier-wise Stock

The

Raw Material Supplier-wise Stock Excel document is a comprehensive tool that tracks inventory levels categorized by each supplier, allowing for precise management of raw materials. It provides detailed insights into stock availability, supplier reliability, and procurement schedules, enabling businesses to optimize supply chain operations and reduce stockouts or excess inventory. Using this document enhances decision-making by offering a clear overview of material inflows, supplier performance, and inventory turnover rates.

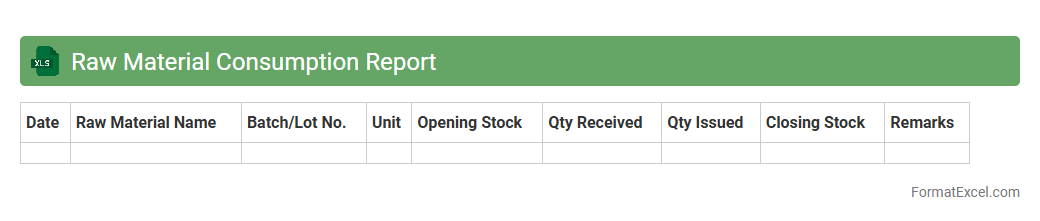

Raw Material Consumption Report

The

Raw Material Consumption Report Excel document tracks the quantity and cost of raw materials used in production over a specific period, providing detailed insights into inventory usage and waste management. It enables businesses to monitor consumption patterns, optimize procurement strategies, and reduce operational costs by identifying discrepancies or inefficiencies in material utilization. This report supports accurate financial reporting and helps maintain better control over supply chain and production processes.

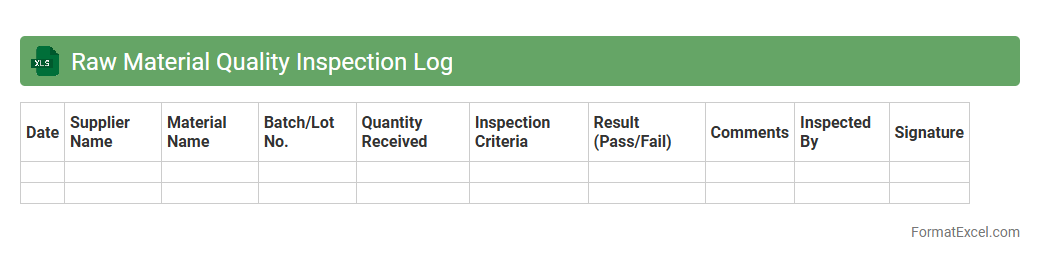

Raw Material Quality Inspection Log

A

Raw Material Quality Inspection Log Excel document systematically records the inspection results of materials received, ensuring compliance with defined quality standards. It helps organizations track defects, maintain traceability, and make data-driven decisions to prevent substandard inputs in production. This log enhances quality control processes, reduces waste, and supports regulatory compliance by providing easily accessible and organized inspection data.

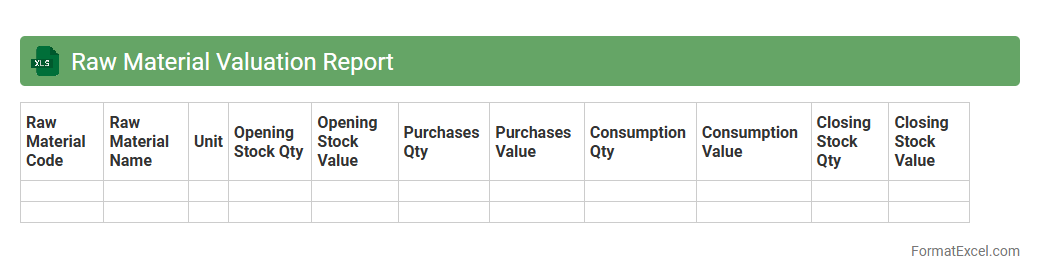

Raw Material Valuation Report

The

Raw Material Valuation Report Excel document provides a detailed assessment of the cost and quantity of raw materials used in production processes. It enables businesses to track inventory values accurately, monitor fluctuations in material costs, and optimize purchasing decisions. This report supports financial analysis, budgeting, and inventory management by offering clear insights into raw material consumption and valuation.

Raw Material Order Tracking

A

Raw Material Order Tracking Excel document is a tool designed to monitor and manage the procurement process of raw materials in manufacturing or production environments. It helps track order dates, quantities, supplier details, delivery status, and payment information, ensuring timely inventory replenishment and avoiding production delays. Utilizing this document improves supply chain transparency, enhances inventory control, and supports efficient decision-making by providing real-time data insights.

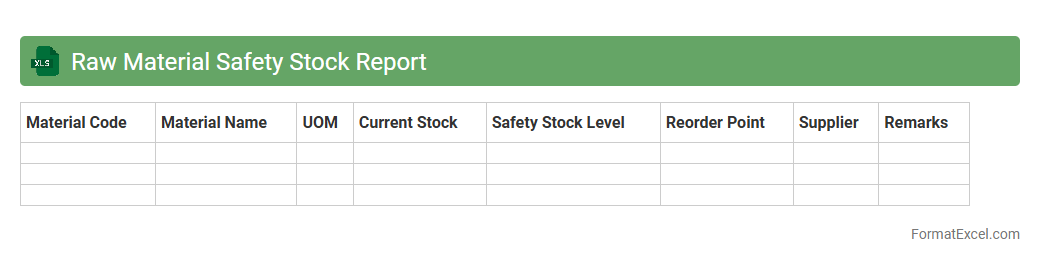

Raw Material Safety Stock Report

The

Raw Material Safety Stock Report Excel document provides a detailed overview of the minimum inventory levels required to prevent production disruptions caused by supply chain variability. It helps businesses maintain optimal safety stock by analyzing consumption rates, lead times, and demand fluctuations, enabling informed decisions on reorder points. This report is valuable for minimizing stockouts, reducing excess inventory, and improving overall supply chain efficiency.

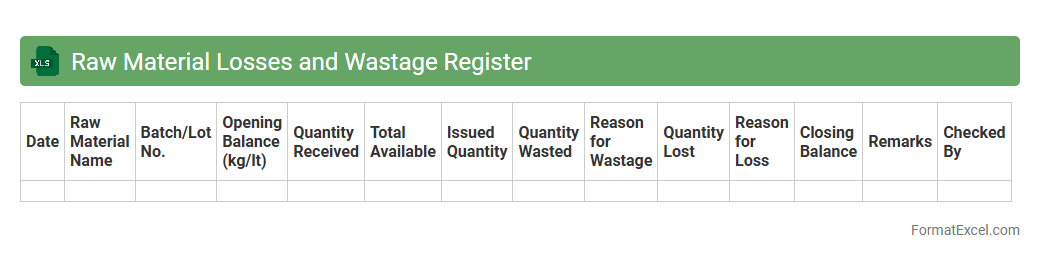

Raw Material Losses and Wastage Register

A

Raw Material Losses and Wastage Register Excel document is a structured record-keeping tool designed to track the quantity and causes of raw material losses during manufacturing or production processes. It helps businesses identify waste patterns, control inventory more effectively, and implement cost-saving measures by minimizing unused or spoiled materials. Maintaining this register supports better resource management and enhances operational efficiency through data-driven decision-making.

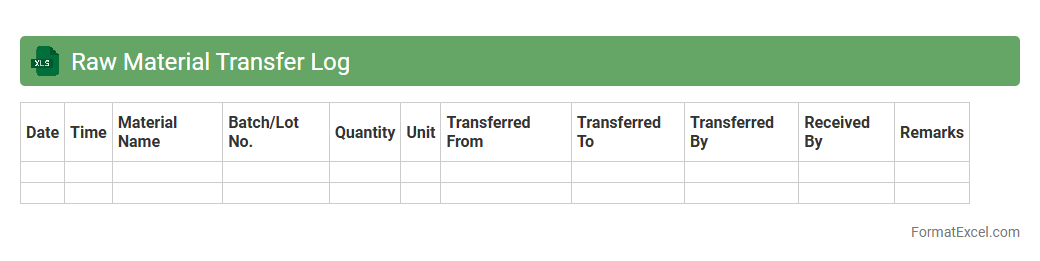

Raw Material Transfer Log

A

Raw Material Transfer Log Excel document is a structured spreadsheet used to track the movement of raw materials within a manufacturing or production environment. It records essential details such as material type, quantity, transfer date, origin, and destination, ensuring accurate inventory management and reducing discrepancies. This log enhances supply chain efficiency by providing clear visibility into raw material usage and facilitating timely replenishment decisions.

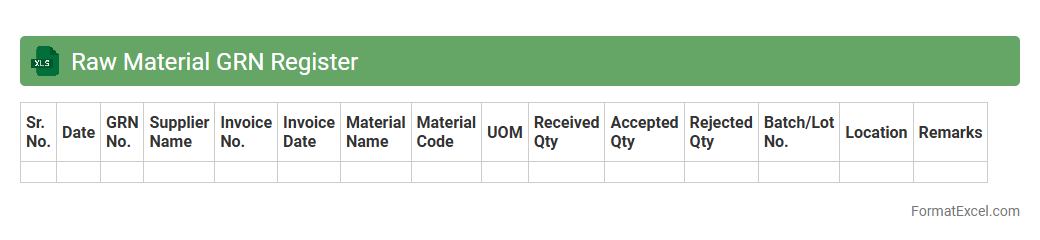

Raw Material GRN Register

The

Raw Material GRN Register Excel document is a detailed record used to track the receipt of raw materials against purchase orders in manufacturing or production environments. It helps ensure accurate inventory management by providing real-time updates on quantities received, supplier details, and quality checks. This register streamlines auditing processes, reduces discrepancies, and enhances overall operational efficiency by maintaining a transparent and organized log of material inflow.

Raw Material Return Register

A

Raw Material Return Register Excel document is a detailed log used to track the return of raw materials to suppliers or storage, recording quantities, dates, reasons for returns, and supplier information. This register helps maintain accurate inventory records, ensures accountability, and facilitates efficient material management by identifying discrepancies and reducing wastage. Businesses can improve procurement decisions and cost control by analyzing return patterns documented in this Excel file.

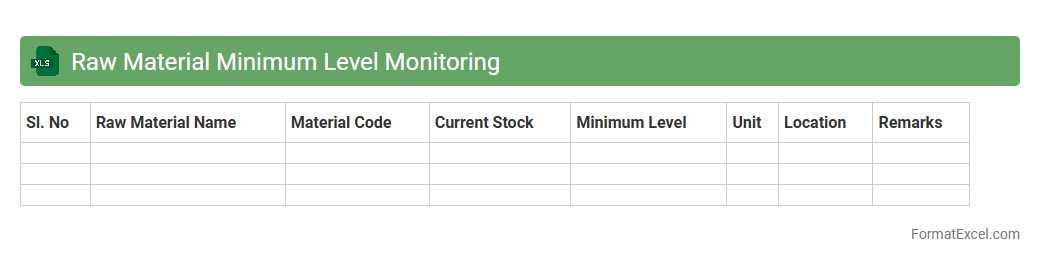

Raw Material Minimum Level Monitoring

The

Raw Material Minimum Level Monitoring Excel document tracks inventory thresholds to ensure timely reordering and prevent production delays. It helps businesses maintain optimal stock levels by providing alerts when raw material quantities fall below minimum set points. This proactive inventory management tool enhances operational efficiency and reduces the risk of stockouts.

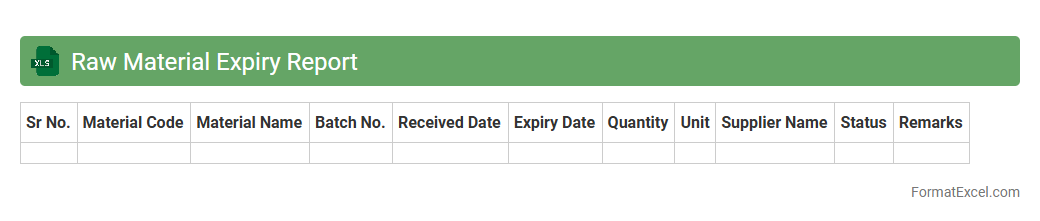

Raw Material Expiry Report

The

Raw Material Expiry Report Excel document tracks the expiration dates of raw materials in inventory, allowing businesses to monitor and manage stock effectively. It helps prevent the usage of expired materials, reduces waste, and ensures compliance with quality standards. By providing timely alerts, this report supports optimal inventory turnover and cost savings in production processes.

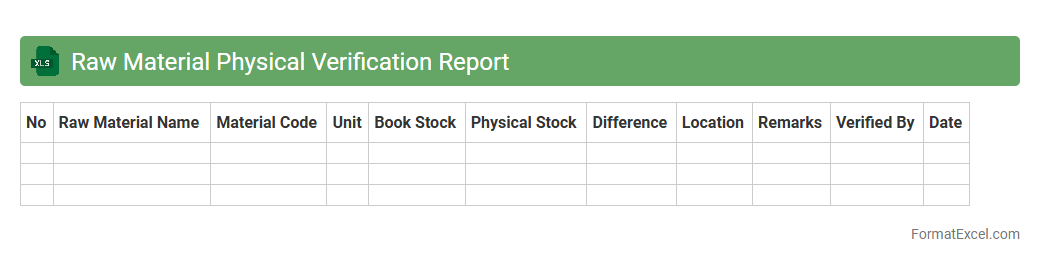

Raw Material Physical Verification Report

The

Raw Material Physical Verification Report Excel document is a detailed inventory record used to compare actual stock of raw materials against recorded quantities in the system. It helps identify discrepancies, ensuring accurate inventory management and minimizing losses due to theft, damage, or data entry errors. This report streamlines audit processes and supports effective procurement planning by providing reliable data on material availability.

Raw Material Pending Orders List

The

Raw Material Pending Orders List Excel document tracks all outstanding purchase orders for raw materials, providing a clear overview of quantities, suppliers, and expected delivery dates. This tool enables efficient inventory management by highlighting pending supplies to avoid production delays. It helps procurement teams prioritize orders and maintain smooth operations through real-time status monitoring.

Introduction to Raw Material Inventory Management

Raw material inventory management involves tracking and controlling the materials used in production processes. Efficient management reduces waste and ensures timely availability of materials. Implementing a structured inventory system is crucial for operational success.

Importance of Raw Material Inventory Formats

Having a standardized raw material inventory format facilitates accurate record-keeping and easy data retrieval. This format helps in maintaining consistency across different inventory checks. A well-designed inventory format simplifies decision-making and resource planning.

Key Components of a Raw Material Inventory Excel Template

An Excel template typically includes columns for material names, quantities, unit price, supplier details, and reorder levels. These elements help track material usage and procurement efficiently. Including all key data fields ensures comprehensive inventory management.

Step-by-Step Guide to Creating an Excel Inventory Format

Begin by listing all raw materials and defining essential columns like quantity and supplier. Use Excel functions for calculations and set up conditional formatting for alerts. Following these steps creates a customized inventory sheet suited to your business needs.

Essential Columns for Raw Material Tracking

Vital columns include Item ID, Description, Quantity in Stock, Unit Cost, Supplier, and Reorder Level. These fields enable effective monitoring and timely procurement of raw materials. Properly structured tracking columns improve inventory transparency.

Best Practices for Organizing Inventory Data in Excel

Keep data clean by using consistent formats, drop-down lists for categories, and freezing header rows. Regularly update the inventory and backup data to prevent loss. Adopting organizational best practices enhances accuracy and efficiency.

Sample Raw Material Inventory Format Templates

Sample templates offer ready-made layouts with built-in formulas and formats for quick implementation. They serve as a great starting point for businesses new to inventory tracking. Using a sample template saves time and reduces setup errors.

Common Mistakes to Avoid in Inventory Sheets

Avoid common errors such as omitting essential columns, inconsistent data entry, and neglecting regular updates. These mistakes can lead to inaccurate inventory data and poor decision-making. Ensuring attention to detail helps maintain a reliable inventory sheet.

Tips for Automating Inventory Management in Excel

Leverage Excel features like macros, pivot tables, and data validation to automate calculations and alerts. Integration with barcode scanners and cloud storage can further enhance efficiency. Automation reduces manual errors and streamlines inventory management.

Free Downloadable Raw Material Inventory Excel Templates

Many websites offer free, customizable Excel templates tailored for raw material inventory tracking. These templates can be downloaded and modified to fit specific business requirements. Utilizing a free downloadable template is cost-effective and convenient.